AZuR's new partner Werba-Chem: sustainable solutions and additives for tire manufacturing

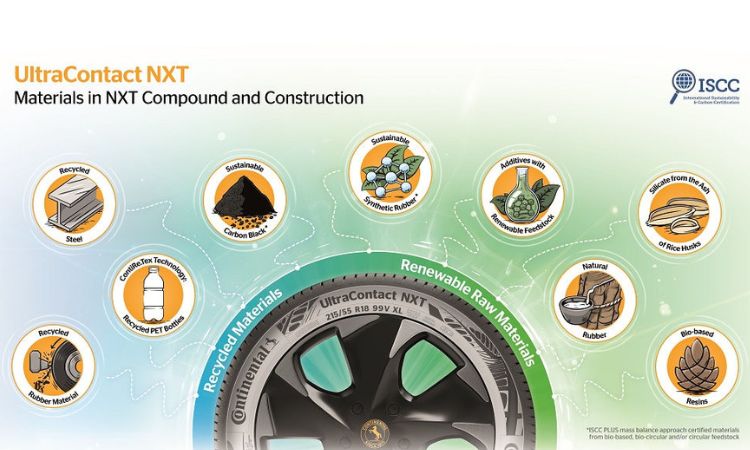

AZuR's new partner Werba-Chem is developing biodegradable additives from renewable raw materials for the climate-friendly production of high-quality tires and rubber products. According to AZuR's recent article, for over 70 years, Austrian company Werba-Chem GmbH has been a reliable partner to the industry. Originally a trading company, it has evolved into a globally sought-after provider of innovative products and solutions, helping customers across various sectors achieve sustainability gains. The self-developed additives and chemicals are key elements in many modern industrial processes, with Werba-Chem focusing on sustainable materials that can remain in use for as long as possible.